How Bruce Lee made Lee Kung Man’s everyday undershirt a fashion icon

How Bruce Lee made Lee Kung Man’s everyday undershirt a fashion icon

The stubbornly small Hong Kong manufacturer does not like collaborations, expansion ... or interviews with the press

BY BERNICE CHAN

13 OCT 2018

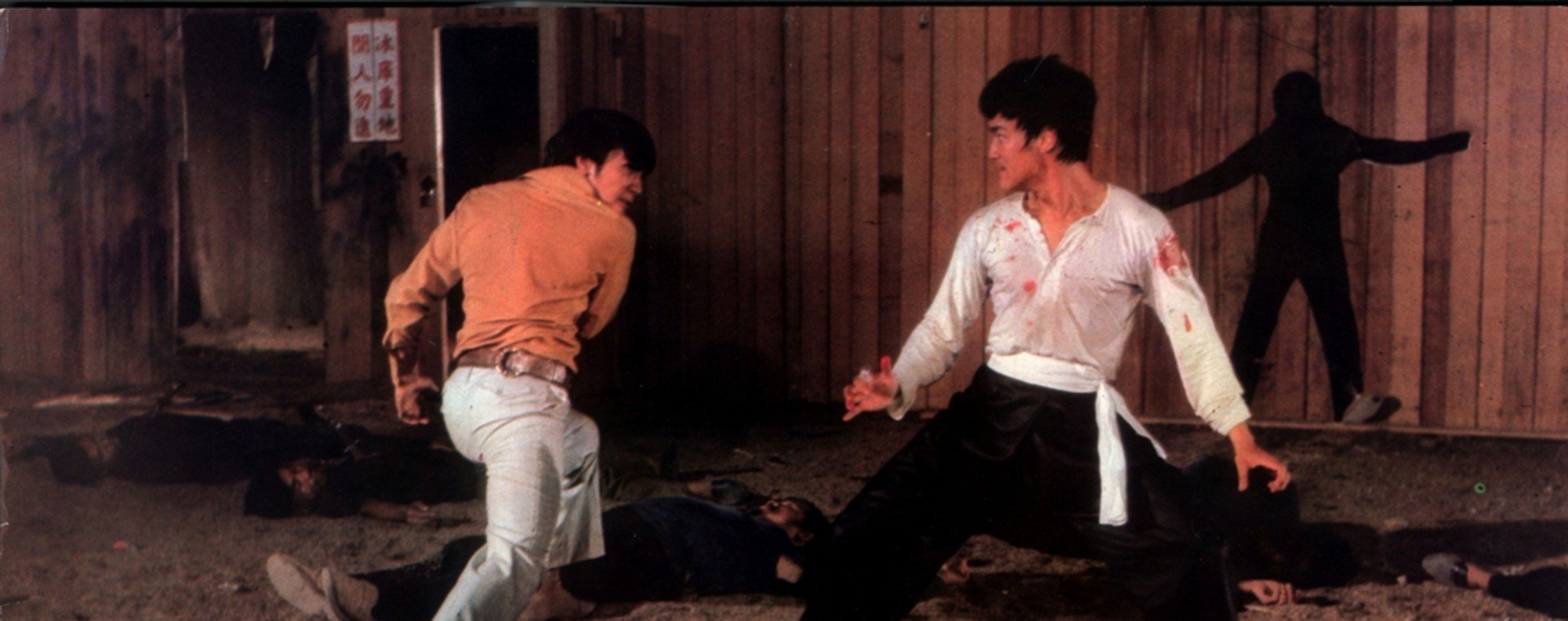

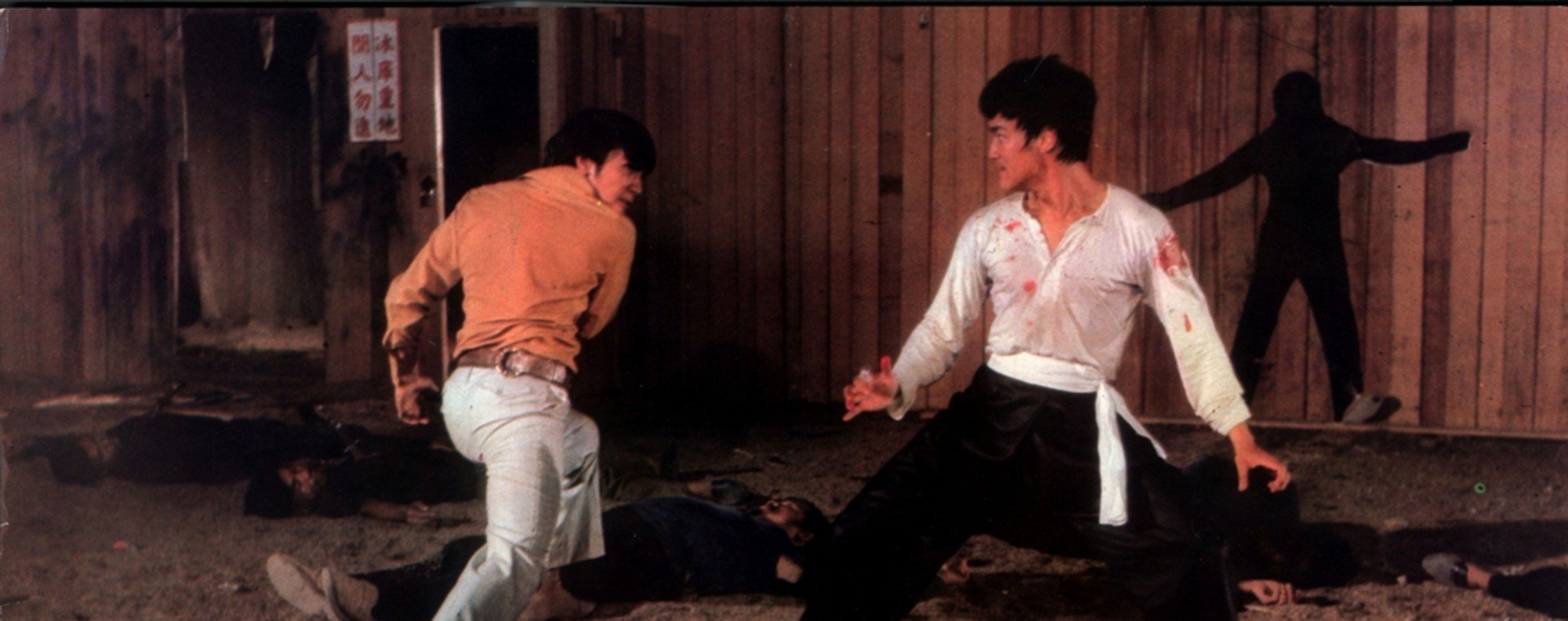

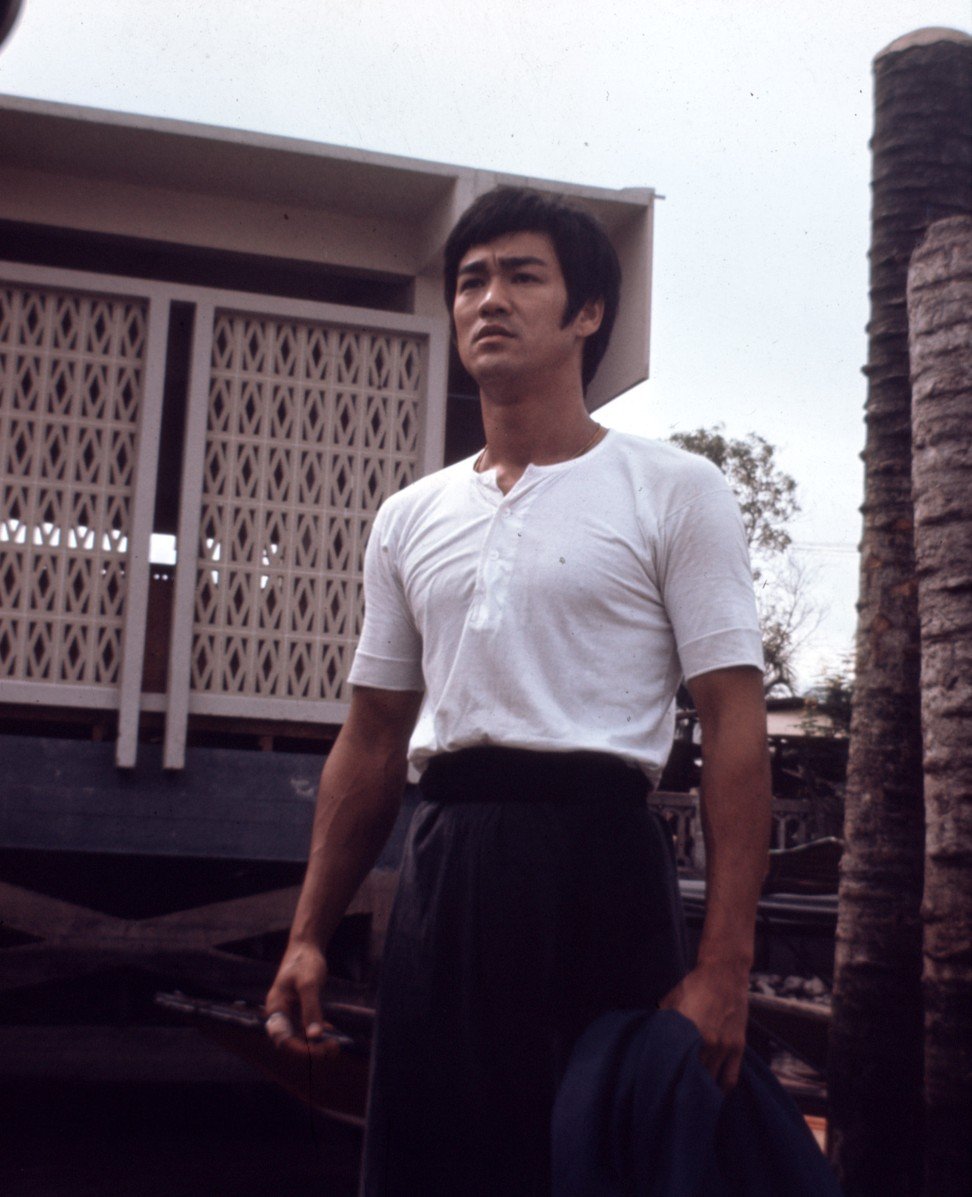

Bruce Lee dressed in a white, round-necked T-shirt with three buttons at the front. It’s an iconic image from the 1970s, thanks to which that humble, lightweight undershirt became famous around the world. Few international fans knew it, but that sought-after cotton garment was made in Hong Kong – and still is.

Lee Kung Man, the media-shy company behind the shirt, was founded in Canton – modern-day Guangzhou – in 1923. In Hong Kong, the firm has been manufacturing that simple but signature product at its Lai Chi Kok factory for decades, selling it in the same packaging and from the same shops – in Sheung Wan, Wan Chai, Sham Shui Po and Mong Kok.

Bruce Lee wearing a Lee Kung Man shirt. Picture: Alamy

Entering a Lee Kung Man store is like going back in time, with the products in cardboard boxes, stacked behind the counter. Customers have to ask to see the merchandise and cannot try anything on. When it comes to the summery undershirt as worn by Lee, the choices are white, white or white, with short, long or no sleeves.

Prices start at HK$45 and rise to HK$270. Not cheap, but roll the fabric between your fingers and you will discover that it is extremely thin yet durable. This quality – coupled with the fact that Lee Kung Man has been doing its thing the same way for almost a century – is what Douglas Young, co-founder of Hong Kong lifestyle label G.O.D. (Goods of Desire), loves about the brand.

“I wear their T-shirts all the time. They are so thin,” he says, describing the fabric used for the garments as “mercerised cotton”, which is produced by treating raw cotton with caustic soda, making it shrink, become more hard-wearing and gain a silk-like texture. “The material is super absorbent so that when you sweat, it evaporates just like that. It’s better than those hi-tech fabrics from Nike. The synthetic fabric is not as good as this cotton.”

In a television advertisement from 1974, an older man, though bundled up against the cold, is shivering while a young man in a Lee Kung Man under*shirt appears perfectly comfortable. “They are known as undergarments; no one wore them ‘out’ – you didn’t see people wearing them,” Young says. “But Bruce Lee made it OK to wear it as a top.”

G.O.D. liberally plunders Hong Kong’s past for the dynamic designs it applies to its apparel and homeware, so it comes as no surprise to discover that Young admires the Lee Kung Man shirt’s retro packaging. The yellow box features an illustration of a prancing Golden Deer, the garment’s brand mark, and the all-important declaration, “Made in Hong Kong”, below.

“Normally, you have to buy three items before they will put them in a box,” Young says, “but I love the boxes so much that I buy three shirts and ask to have them put into three separate boxes.”

Some years ago, G.O.D. attempted to collaborate with Lee Kung Man. “We had to beg them to do the collabor*ation, and the people at Lee Kung Man are very stubborn,” Young says. “We wanted to take the existing material they use and make it more contemporary looking, but they refused to manufacture the clothing according to our design. In the end, we had to take their finished product and then get someone else to do the modification.”

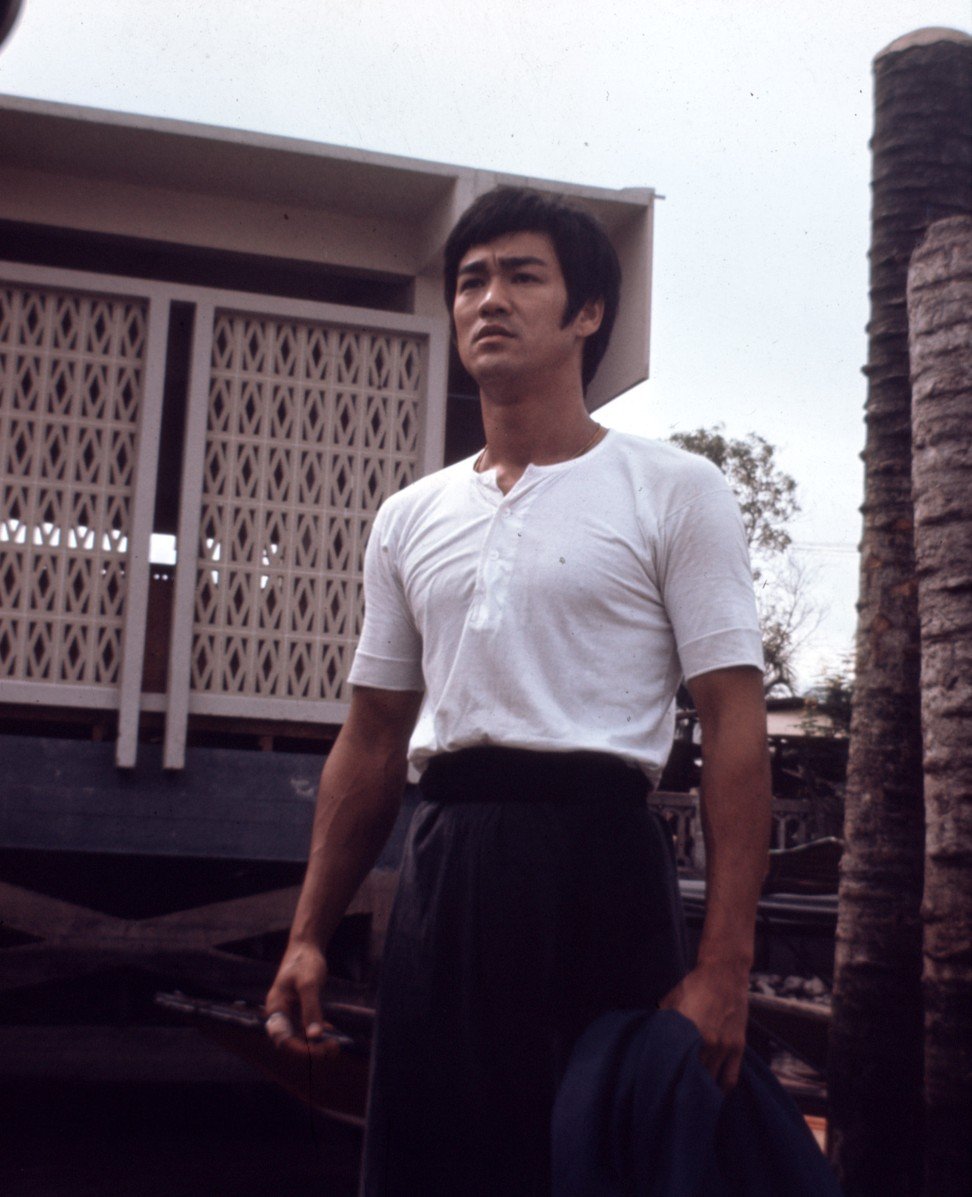

Douglas Young, co-founder of Hong Kong lifestyle label G.O.D. (Goods of Desire), in one of his Lee Kung Man undershirts. Picture: Tory Ho

Alan See, co-founder of bespoke Hong Kong tailoring and accessories retailer The Armoury, also attempted to collaborate with Lee Kung Man. “I tried to work with them and they had no email, so I had to fax everything to their friend’s place,” says the Malaysian-born See, who occasion*ally wears Lee Kung Man cotton T-shirts, considering them good for layering. “Then they got the fax and we communi*cated like this, back and forth. It took so long to do things.”

See says that what makes Lee Kung Man undershirts so comfortable is their tube-knit design, which means no side seams. “The machines [on which they are made] are almost obsolete,” he adds, “so they have to cannibalise other machines to repair them.”

Lee Kung Man founder Fung Sau-yu was born in 1889 in Shun Tak (today the Shunde district of Foshan city, Guangdong province), and made his living as a young man selling Western goods in Canton. In 1923, he bought six hand-operated hosiery-making machines, giving his new company a name that means literally “benefiting workers and farmers”.

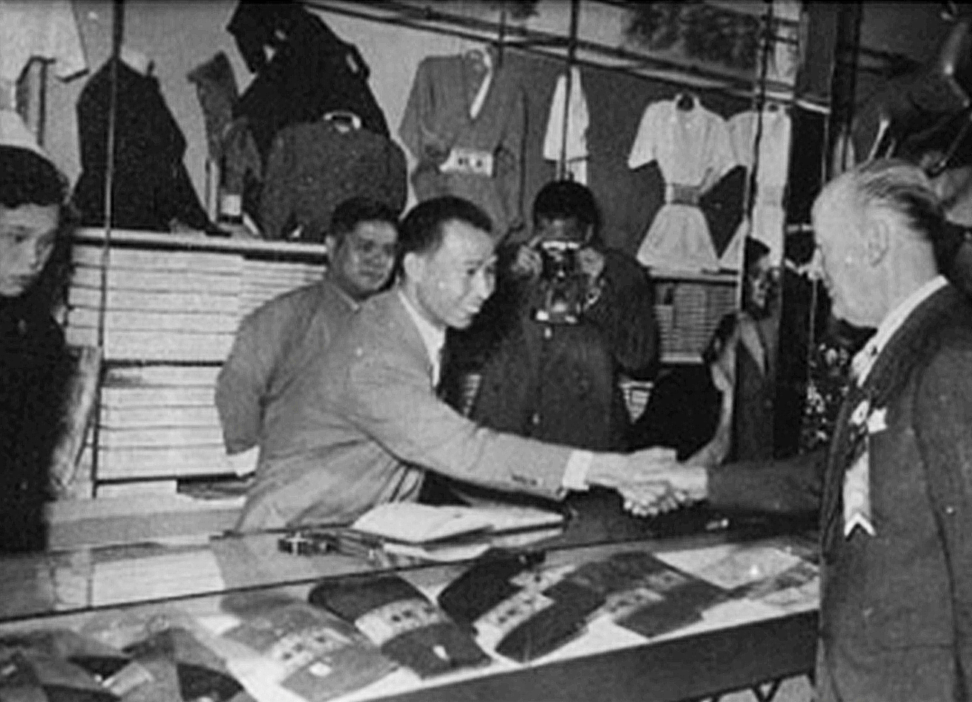

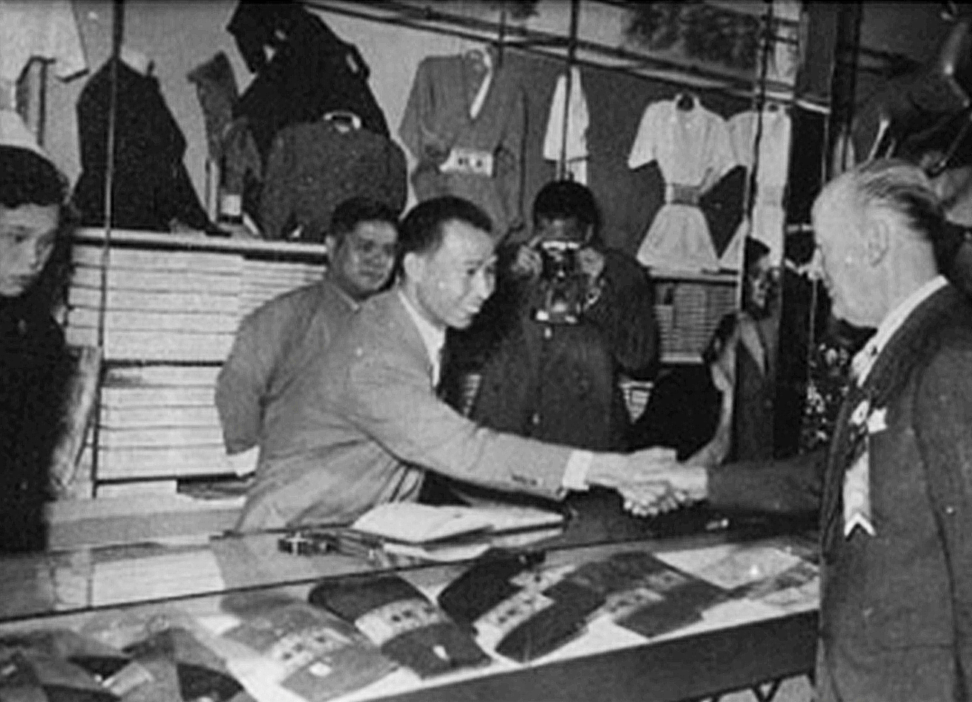

Hong Kong governor Alexander Grantham meets employees at the Lee Kung Man booth at the 1957 Hong Kong Products Expo. Picture: Lee Kung Man

Using wool imported from Britain, Lee Kung Man quickly gained a reputation for quality and, by 1925, the firm boasted 20 machines. A few years later, Fung added singlets to the product line and opened a factory on Hong Kong’s Des Voeux Road Central.

When Japanese troops invaded Canton in 1938, the Lee Kung Man factory there was destroyed, so Fung moved his operations to Shun Tak, and then, in 1940, he left for Hong Kong. The next year, however, with the Japanese occupa*tion, Fung suspended operations, devoting his time to serving the Taoist temple Fung Ying Seen Koon, in Fanling.

With the war’s end in 1945, Fung returned to Canton and restarted manufacturing, enjoying brisk sales before the 1949 Communist assumption of power in China. With his mainland operation nationalised, Fung again fled to Hong Kong, spending the rest of his days in Fanling, delegating to his sons and nephews. He died in 1952.

When Post Magazine calls Lee Kung Man’s head office, in Wan Chai, to request an interview with the owners, the person who answers does so brusquely, in the negative, and puts the phone down, suggesting the company has no need or desire for media attention. Business, one assumes, must be good.

In 1985, however, a reporter from the South China Morning Post did manage to interview Fung Ka-cheung, son of Fung Sau-yu, when Golden Deer undershirts cost HK$54.

Back then, the company produced thousands of items a year (“And Mr Fung expects that they always will”), and the managing director said quality remained the priority, the shirts made using 100 per cent natural cotton sourced from Switzerland and Britain, and boasting a fine count of 100 threads per square inch compared with the coarse 24-count fabric used in many competing products.

Reply With Quote

Reply With Quote